Application Highlight: Easy Particle Size Adjustment

Advanced materials often require multiple particle size grades to deliver optimal performance across different applications. Traditionally, achieving this range, especially from microns to submicrons, has required using separate equipment for each size specification.

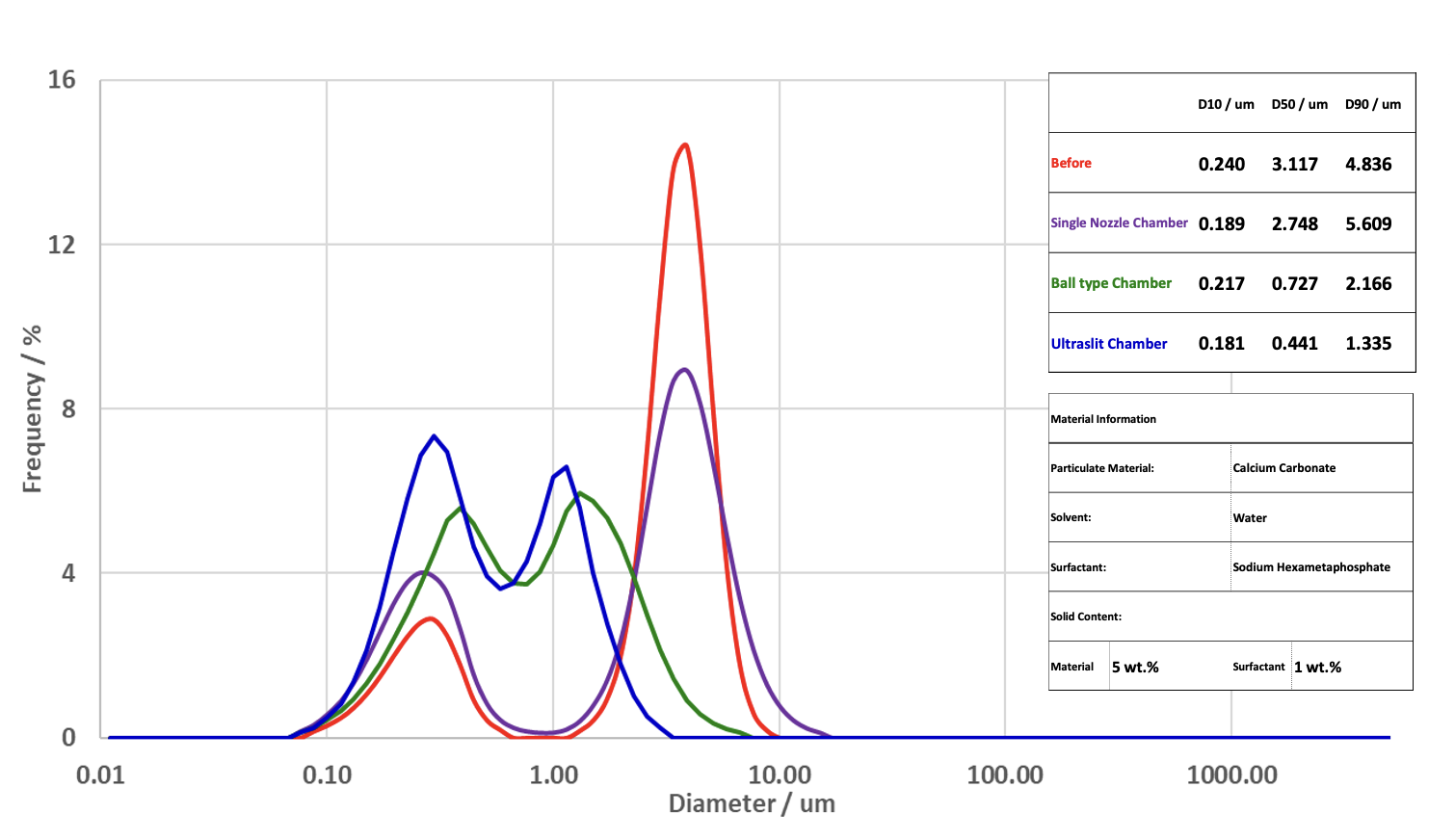

Sugino’s Star Burst changes that. Its flexible design offers broad condition adjustability and a wide selection of interchangeable processing chambers, enabling quick particle size tuning. Pressure adjustments and re-circulation control provide precise size optimization, while rapid chamber swaps allow users to produce a full range of particle sizes without investing in additional systems.

This capability expands product offerings, accelerates R&D, and reduces both capital investment and facility space requirements.

Particle Size Reducation Performance: Chamber Comparison

Key Takeaways

-

Multiple particle size grades with one system for operational flexibility

-

Faster product development thanks to easy chamber swaps

-

Reduced capital and facility footprint - one milling platform, modular chambers

-

Scalable, repeatable control for consistency

Versatile Processing

Sugino's Star Burst system can be applied to a wide range of materials and applications. Star Burst’s flexibility and efficiency make it a powerful tool for advanced material development across industries.

Explore how Star Burst compares to other methods: