Cavitation Water Jet Peening

An innovative processing technology that improves the fatigue strength and life of metal parts by utilizing water.

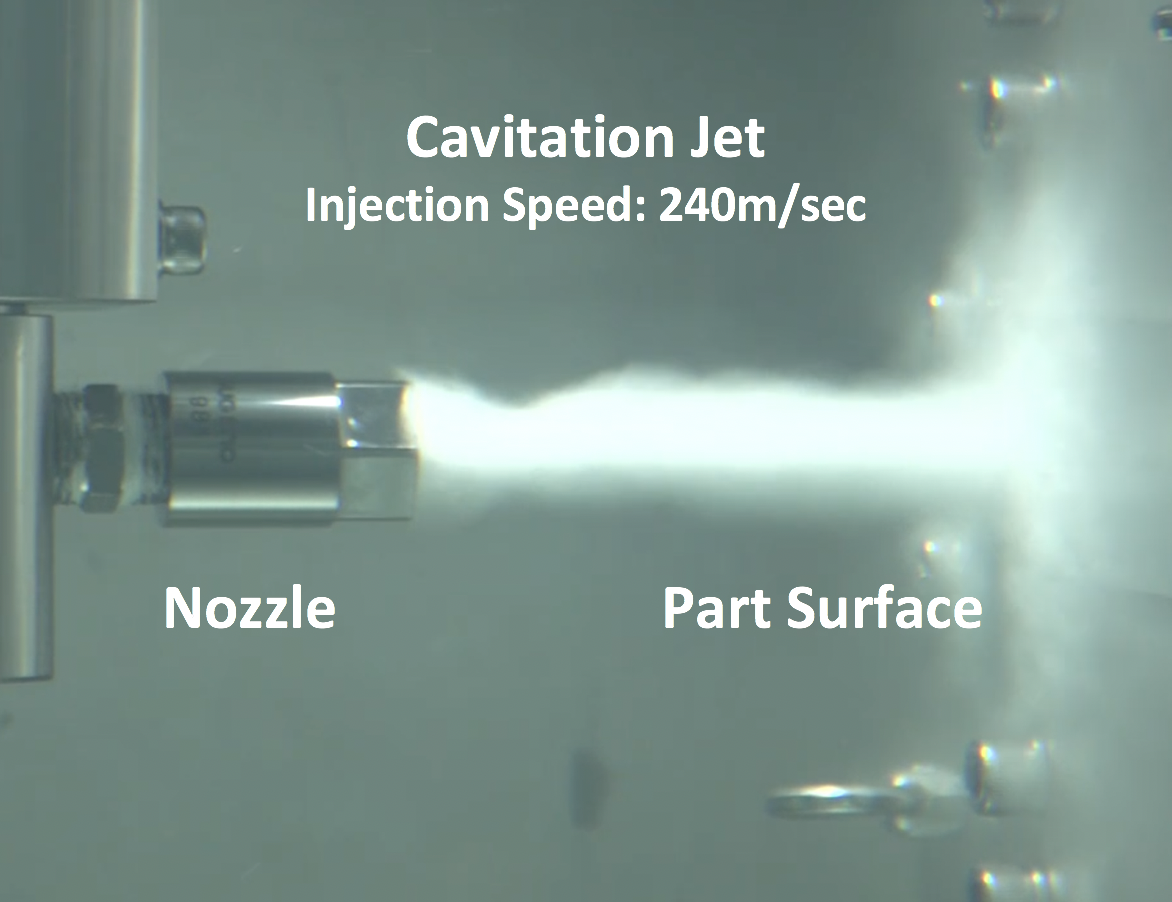

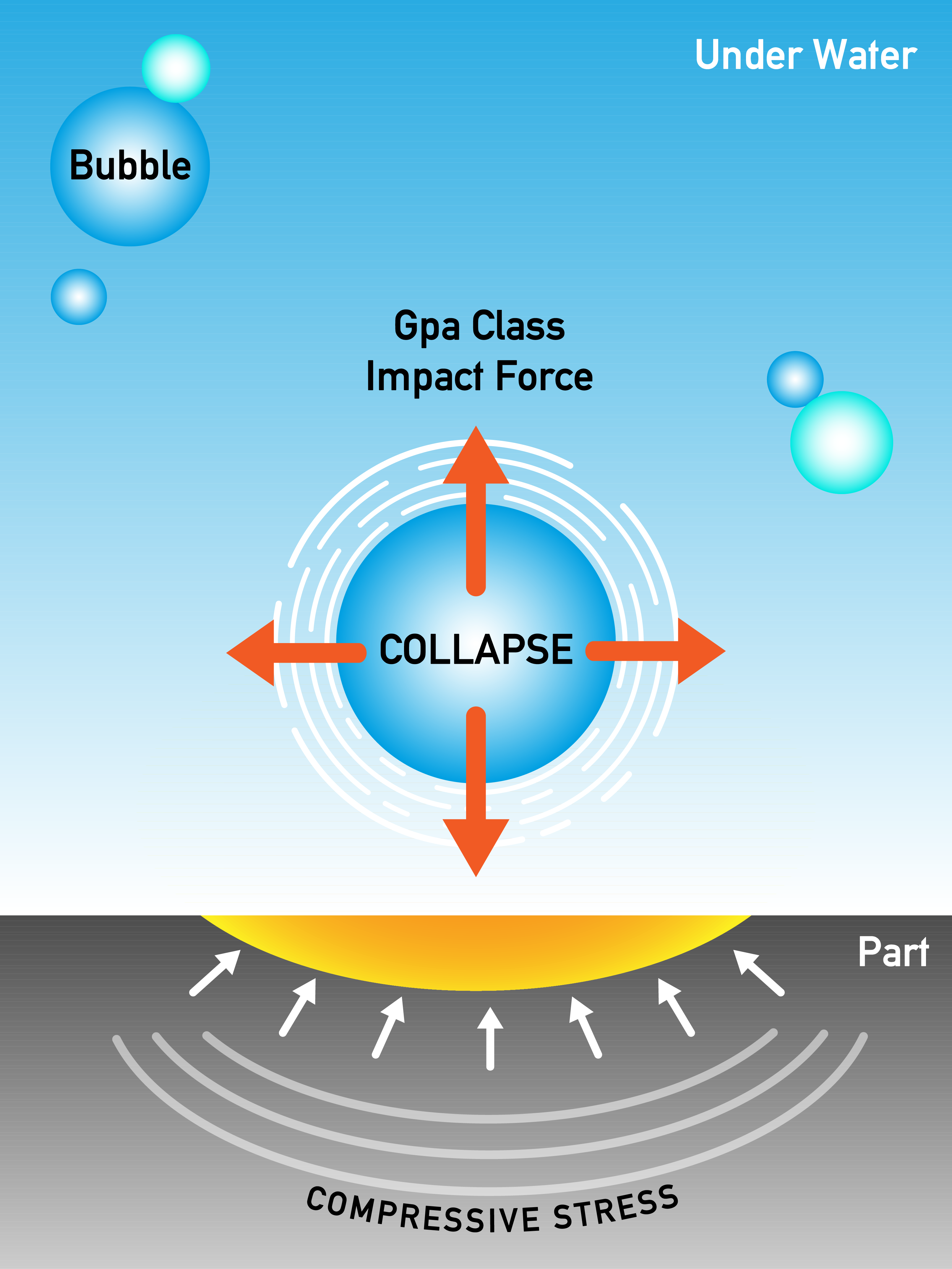

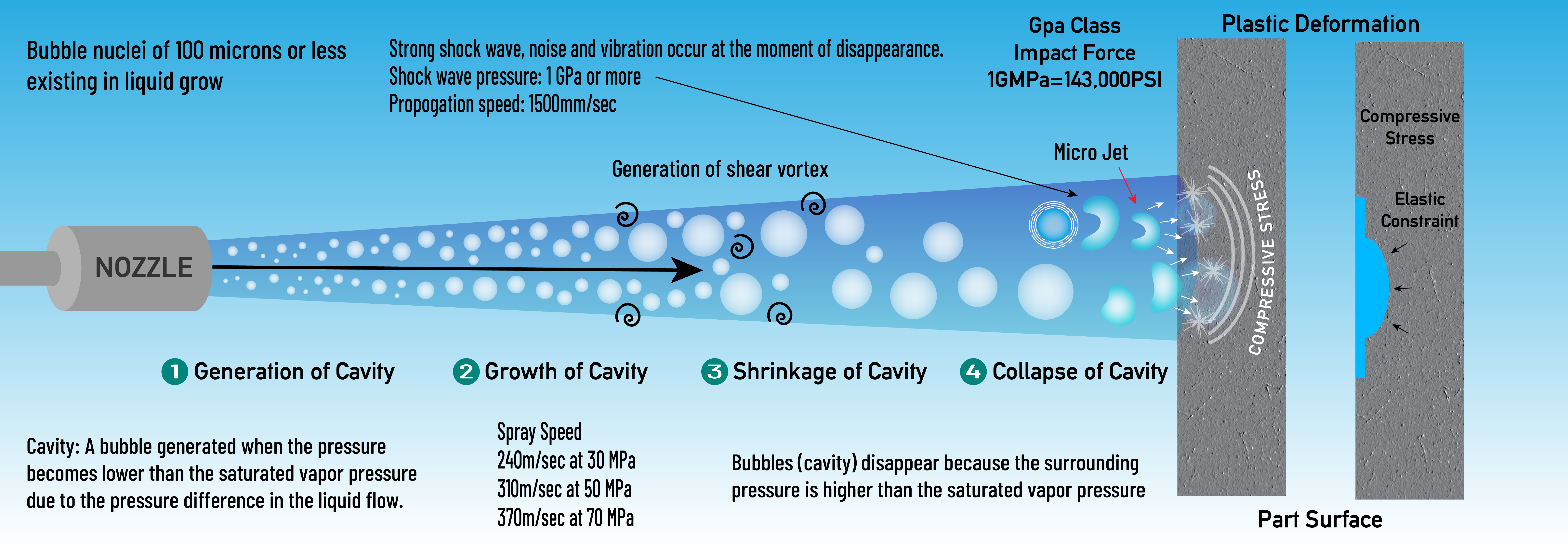

High pressure water is jetted into the water at high speed from a special cavitation-promoting (air bubble) nozzle to cause cavitation, and GPa (gigapascal) class impact force when bubbles collapse near the workpiece produces a peening effect.

Watch to learn about what happens under the surface inside the CWJP system.

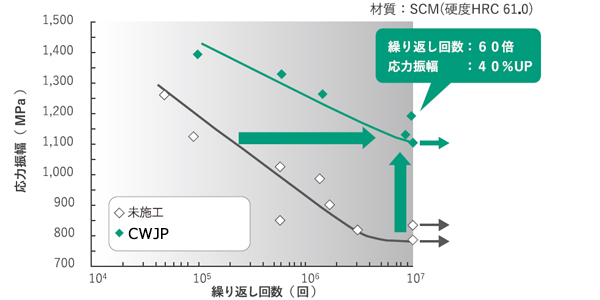

Increased fatigue strength:

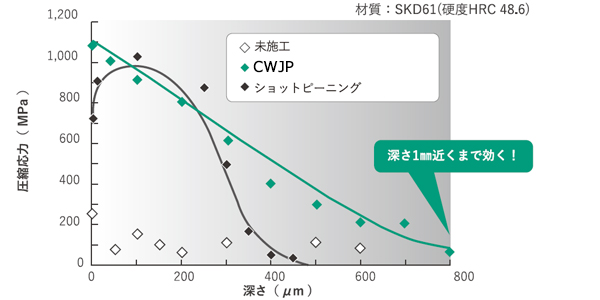

Applying compressive stress to a depth of about 1mm from the surface.

Longer life:

Improves fatigue strength and life.

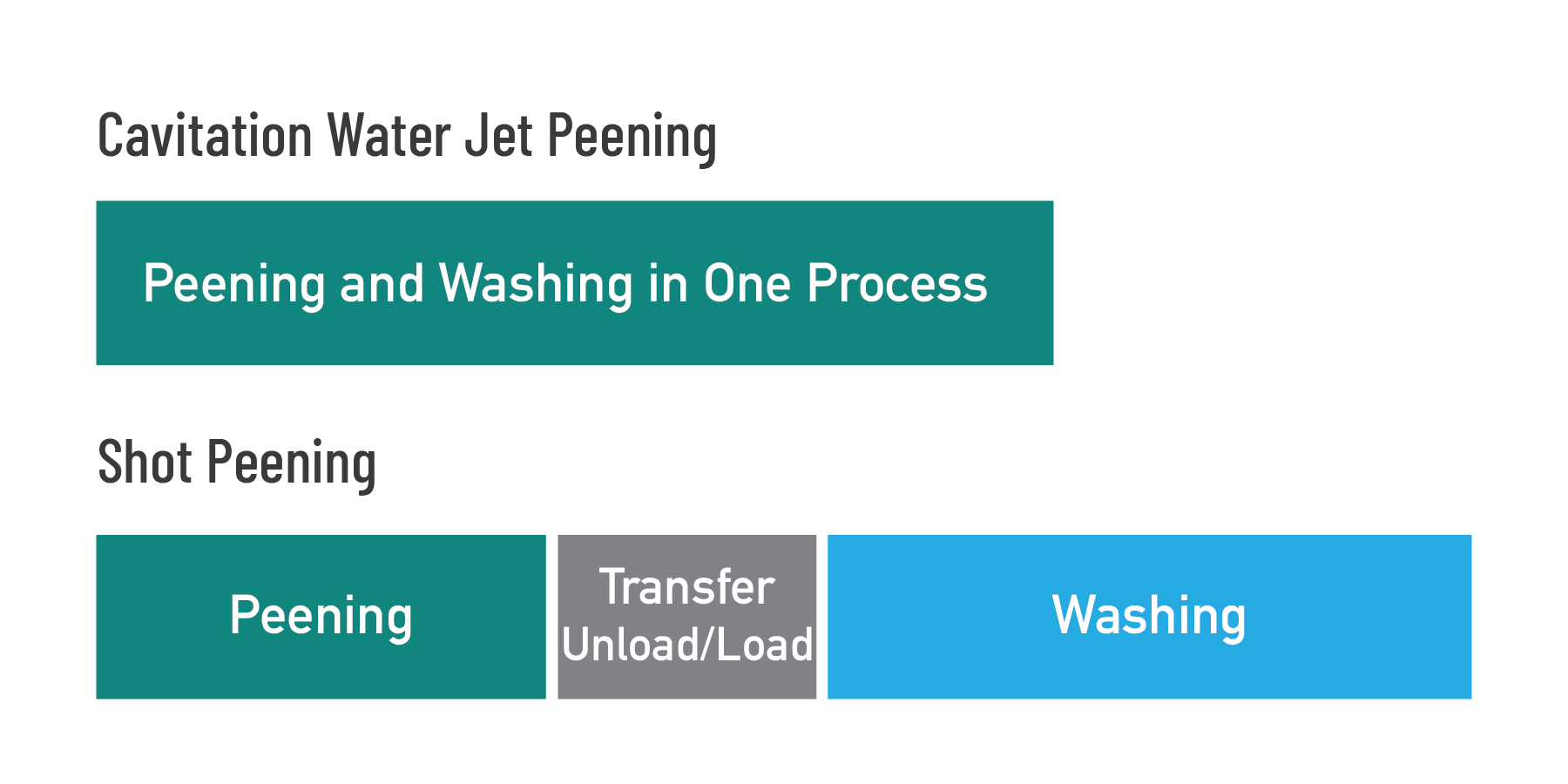

Clean processing method:

Shotless processing method using only water, no cleaning process required.

Applications

Strength and long life:

Increased fatigue strength of steel and aluminum alloys

Prevention of stress corrosion cracking:

Welded parts of structures

Removal of undissolved surface, surface finish:

Post processing for additive manufacturing part

Improved Fatigue Strength

Long Life

A clean processing method

Shotless processing method

Uses only water

No cleaning process required

Sugino Harnesses the Power of Water

Testing gets you the answers you need about our technology.

Testing is available at our Technology Center to help you learn if Cavitation Water Jet Peening fits your needs.