Application Highlight: hBN Exfoliation

Hexagonal boron nitride (hBN) is widely used in batteries to improve safety, thermal management, and performance by acting as an electrically insulating yet highly thermally conductive material. This prevents thermal runaway, a dangerous overheating event, especially important in electric vehicle (EV) batteries. Its electrical insulation prevents short circuits between cells or with other components.

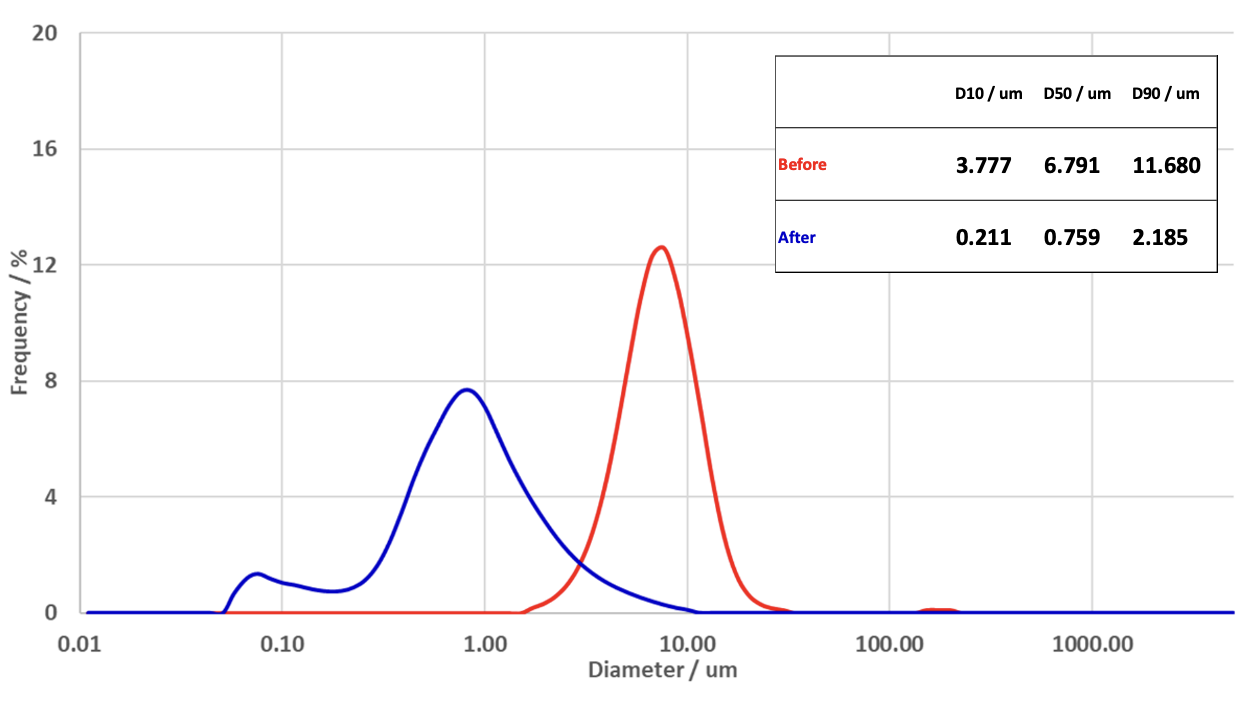

With Star Burst wet jet milling, hBN can be exfoliated in water or other solvents. The technology exfoliates hBN layers by collision, all while preserving the aspect ratio of the materials.

This approach significantly enhances the thermal conductivity and the electrical insulation performance of hBN.

Before and After: Particle Size Distribution of Star Burst Processing

Key Takeways

-

Directly addresses thermal runaway risk

-

Exfoliation enhances thermal conductivity and improves thermal pathways

-

Maintains hBN’s intrinsic electrical insulatio

-

Water- or solvent-based processing for manufacturing flexibility

Versatile Processing

Sugino's Star Burst system can be applied to a wide range of materials and applications. Star Burst’s flexibility and efficiency make it a powerful tool for advanced material development across industries.

Explore how Star Burst compares to other methods: