Think You've Got Specs We Can't Achieve?

Cellulose, chitin and chitosan nanofiber "BiNFi-s"

Biomass Nanofiber

"BiNFi-s" is a series of ultra-fine fiber which is produced by SUGINO MACHINE's ultra-high pressure water jet technology. It made from biomass like cellulose, chitin, and chitosan. The size is about 10-20nm width and several ㎛ average.

In general, cellulose nanofibers/nano-cellulose, chitin nanofibers, and the like are used as raw materials. Applied development and research has been actively conducted in Japan and overseas in recent years.

It has low linear thermal expansion, effect elasticity, transparency, biocompatibility, antibacterial features, improvement of physiological functions, high strength, high aspect ratio, high specific surface area, high viscosity, high shape retention, and high hydrophilicity, and is expected to be used in a variety of fields.

Notice

018.06.12 The BiNFi-s pages have been updated.

A wide range of BiNFi-s with various characteristics achieved by Water jet method!

Reinforcement

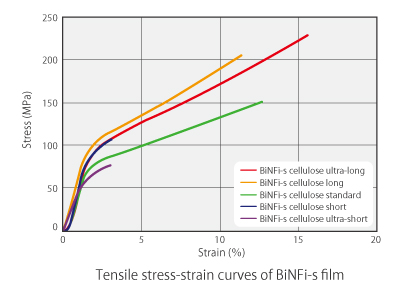

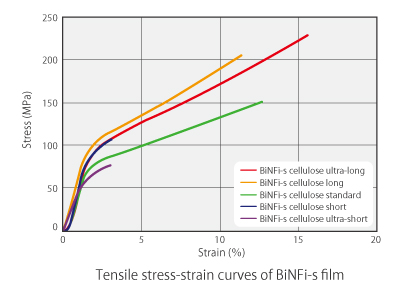

BiNFi-s has a long fiber length type effective as a reinforcing material.

BiNFi-s becomes a film form when dried.

At this time, as the length of the fiber is longer, the number of contact points between the fibers is increased, and the strength of the film is increased.

When BiNFi-s is used as a resin reinforcement material, the longer the fiber length is, the better the strength can be expected.

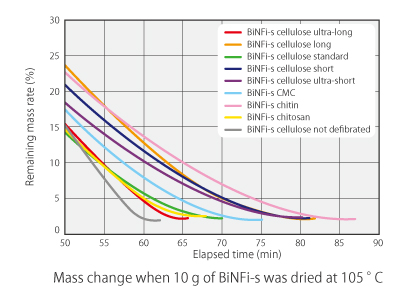

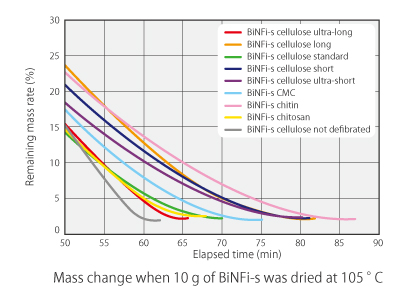

Water retentivity

BiNFi-s has several types of raw materials and different fiber length types, which is effective for improving water retention.

The conversion of raw materials into nanofibers increases the surface area by about 100-fold.

The higher the specific surface area, the more hydroxyl groups in contact with the water, the more hydrophilic it is, and the less likely it is to lose mass.

BiNFi s-chitin has a higher water retention due to its smaller textile diameter than BiNFi s-cellulose. In BiNFi s-cellulose, the shorter the fiber length, the higher the specific surface area, resulting in higher water retention.

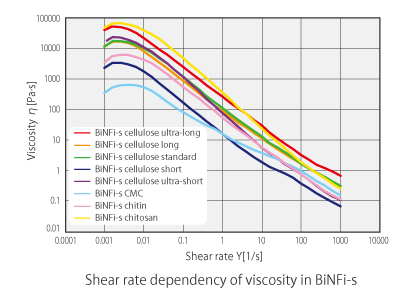

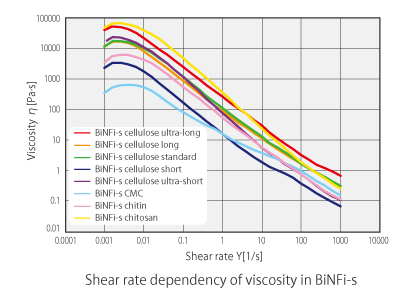

Viscosity enhancement

BiNFi-s has several types of raw materials and different fiber lengths, which are useful for the adjustment of viscosity.

All BiNFi-s are pseudoplastic fluids whose viscosity decreases with increasing shear rate.

Therefore, "a fluid with high viscosity but low viscosity when applied with force" can be produced. The shear rate dependency varies depending on the type of raw material and the textile length. Therefore, You can choose according to your purpose.

Dispersion and emulsion stability

The three-dimensional networks of BiNFi-s can be used to disperse and stabilize particles. For example, if the container is shaken, the particles will move and the particles will be dispersed and stabilized at the moment the container is stopped.

In addition, BiNFi-s adsorbs on the surface of oil droplets and stables them in water, thereby emulsifying them.

Cellulose, chitin and chitosan nanofiber "BiNFi-s"

Biomass Nanofiber

"BiNFi-s" is a series of ultra-fine fiber which is produced by SUGINO MACHINE's ultra-high pressure water jet technology. It made from biomass like cellulose, chitin, and chitosan. The size is about 10-20nm width and several ㎛ average.

In general, cellulose nanofibers/nano-cellulose, chitin nanofibers, and the like are used as raw materials. Applied development and research has been actively conducted in Japan and overseas in recent years.

It has low linear thermal expansion, effect elasticity, transparency, biocompatibility, antibacterial features, improvement of physiological functions, high strength, high aspect ratio, high specific surface area, high viscosity, high shape retention, and high hydrophilicity, and is expected to be used in a variety of fields.

Notice

018.06.12 The BiNFi-s pages have been updated.

A wide range of BiNFi-s with various characteristics achieved by Water jet method!

Reinforcement

BiNFi-s has a long fiber length type effective as a reinforcing material.

BiNFi-s becomes a film form when dried.

At this time, as the length of the fiber is longer, the number of contact points between the fibers is increased, and the strength of the film is increased.

When BiNFi-s is used as a resin reinforcement material, the longer the fiber length is, the better the strength can be expected.

Water retentivity

BiNFi-s has several types of raw materials and different fiber length types, which is effective for improving water retention.

The conversion of raw materials into nanofibers increases the surface area by about 100-fold.

The higher the specific surface area, the more hydroxyl groups in contact with the water, the more hydrophilic it is, and the less likely it is to lose mass.

BiNFi s-chitin has a higher water retention due to its smaller textile diameter than BiNFi s-cellulose. In BiNFi s-cellulose, the shorter the fiber length, the higher the specific surface area, resulting in higher water retention.

Viscosity enhancement

BiNFi-s has several types of raw materials and different fiber lengths, which are useful for the adjustment of viscosity.

All BiNFi-s are pseudoplastic fluids whose viscosity decreases with increasing shear rate.

Therefore, "a fluid with high viscosity but low viscosity when applied with force" can be produced. The shear rate dependency varies depending on the type of raw material and the textile length. Therefore, You can choose according to your purpose.

Dispersion and emulsion stability

The three-dimensional networks of BiNFi-s can be used to disperse and stabilize particles. For example, if the container is shaken, the particles will move and the particles will be dispersed and stabilized at the moment the container is stopped.

In addition, BiNFi-s adsorbs on the surface of oil droplets and stables them in water, thereby emulsifying them.