Precision Technologies Engineered for The Future

Sugino is paving the way into the 21st century and beyond by creating advanced technologies through innovative engineering and research. Together with our clients in aerospace, automotive, construction, manufacturing, energy, agriculture and other industries, we are constantly improving these technologies so we can meet ever-changing specifications and tackle any challenge.

Read more about our technologies below

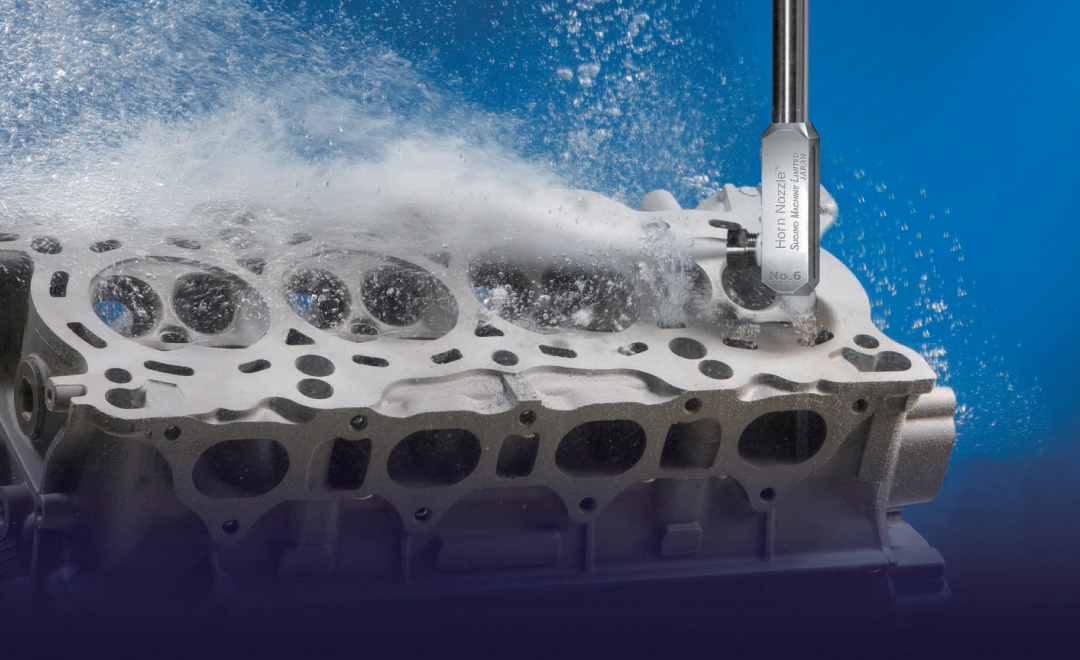

High Pressure Washing and Deburring Technology

Our high pressure washing technology effectively deburrs the hardest metals on earth (Inconel, Titanium) at tolerances that no one else can match. We have a deep history in developing the technologies that lead to today's washing and deburring machines. We’re currently supplying high pressure washers to major automotive manufacturers to achieve a safer, and more environmentally friendly way to make cars.

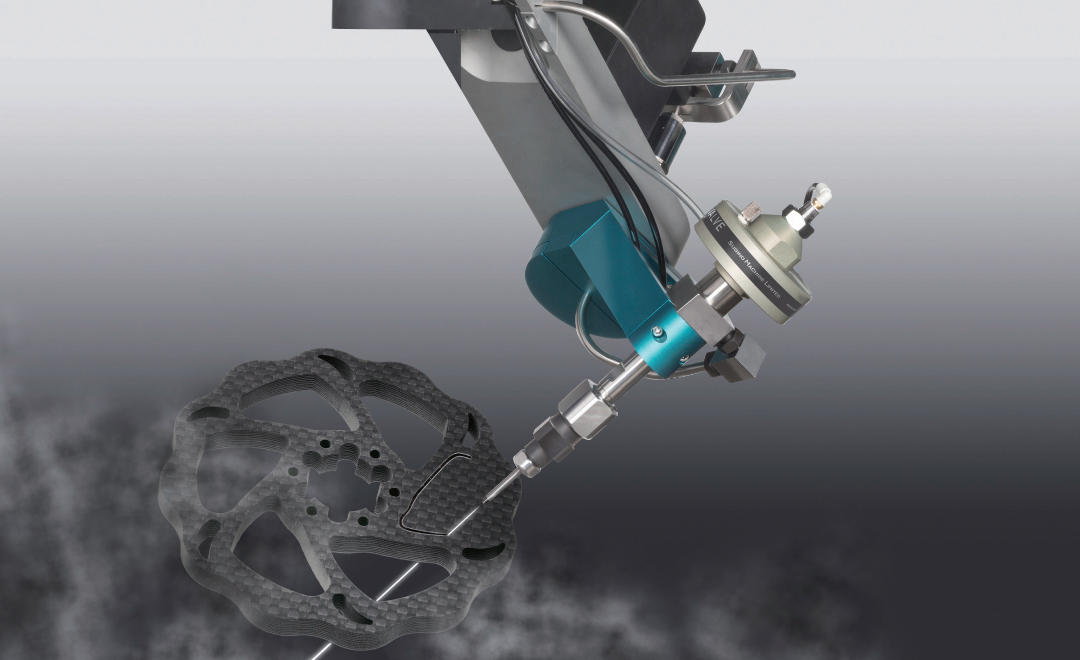

Precision Deburring

Our self-compensating deburring technologies deliver reliable, precision repeatability and are designed for hard tool deburring of all materials and part shapes. Our technologies can be used in many applications such as deburring pipe ports/holes (underside as well), casting profiles, brushing applications, robot applications, and more.

Precision Cutting Technology

Our cutting technology utilizes the energy contained in high-speed, high-density ultra high-pressure water to cut materials. Water is pressurized up to 6,000 atm, and sprayed through a 0.1mm diameter nozzle. Applications for this technology are extensive, including car bumpers and interiors as well as concrete structures and specialty materials for the aerospace industry.

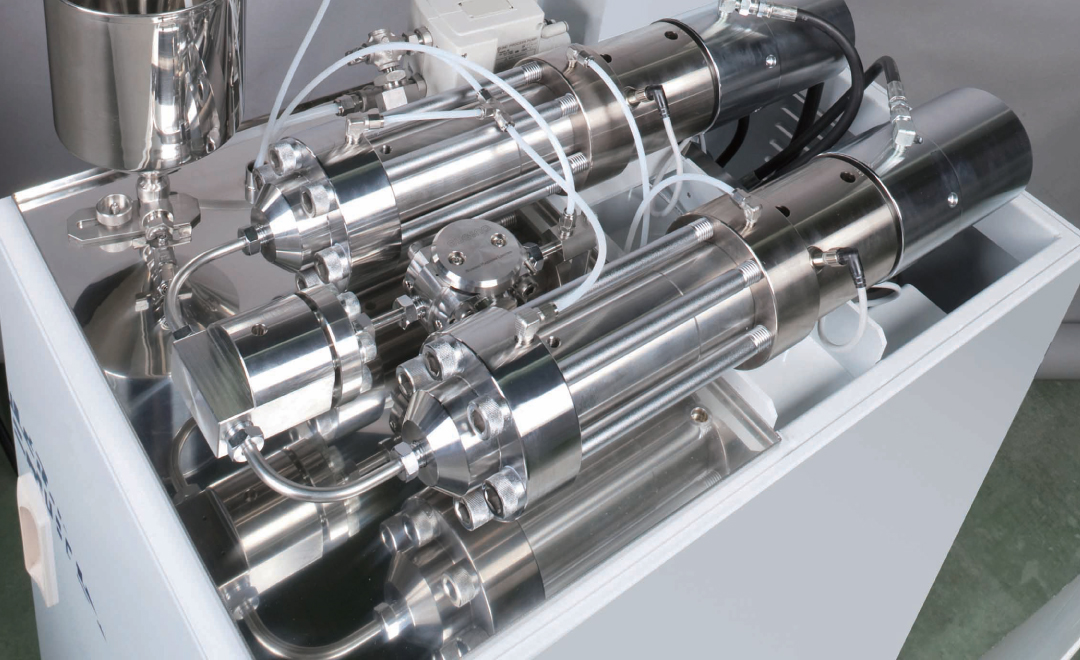

Atomizing Technology

Our atomization technology was developed from our water jet systems and allows tiny particles to be manufactured, free of impurities. As a matter of fact, Sugino's atomization equipment is being recognized as the next generation of nanotechnology. Production sites that require an ultra-clean environment, such as cosmetics, pharmaceuticals and electronic parts rely on us for atomizing technology.