Eliminate Manual Bottlenecks. Deliver Consistent Edge Quality. Save Costs.

Manual deburring slows you down and adds variables to quality and labor costs that machine shops can no longer afford.

The process is labor-intensive, inconsistent, difficult to staff, and nearly impossible to scale. As part complexity increases and skilled labor becomes harder to find, hand deburring turns into a production bottleneck, slowing throughput, introducing variability, and driving up cost per part.

Automating deburring replaces manual finishing with a repeatable, controlled, and scalable process so deburring no longer limits your operation.

Why Manual Deburring Fails in Modern Production

During machining of metal parts, unwanted protrusions called burrs often form, making the deburring process essential for quality production results. This process is often done by hand which presents challenges including human error, the risk of injury, and quality requirements that need repeatability and consistency.

In addition, as manufacturing faces labor shortages the demand for automated deburring solutions continues to increase.

However, deburring with a machining center or robot may not always deliver the desired results. Several factors, such as cutting tool wear, variations in workpiece dimensions, and mounting errors, can lead to inconsistent burr sizes and shapes, complicating the automation process.

Manual deburring relies heavily on operator skill and judgement. That creates challenges you probably know all too well:

Inconsistent edge quality from part to part

Hidden labor costs tied up in non-value-added finishing

- Production bottlenecks that limit machine utilization

Operator fatigue and safety risks

Rework and inspection issues caused by over- or under-deburing

The Smarter Alternative: Automated Float Deburring

This is where Float Deburring comes in - Barriquan provides a machining method with a floating mechanism that aligns the tool perfectly with the workpiece's shape, preventing over-shaving and ensuring that no burrs are left behind. The tool maintains a consistent pressure along the workpiece, and self-compensates. It delivers precise and reliable results every time.

Integrated with robots or CNC machines, the system automatically compensates for:

- Part tolerances

- Tool wear

- Surface variation

The result is consistent burr removal cycle after cycle, without relying on operator “feel” or tribal knowledge.

Different Methods of Float Deburring

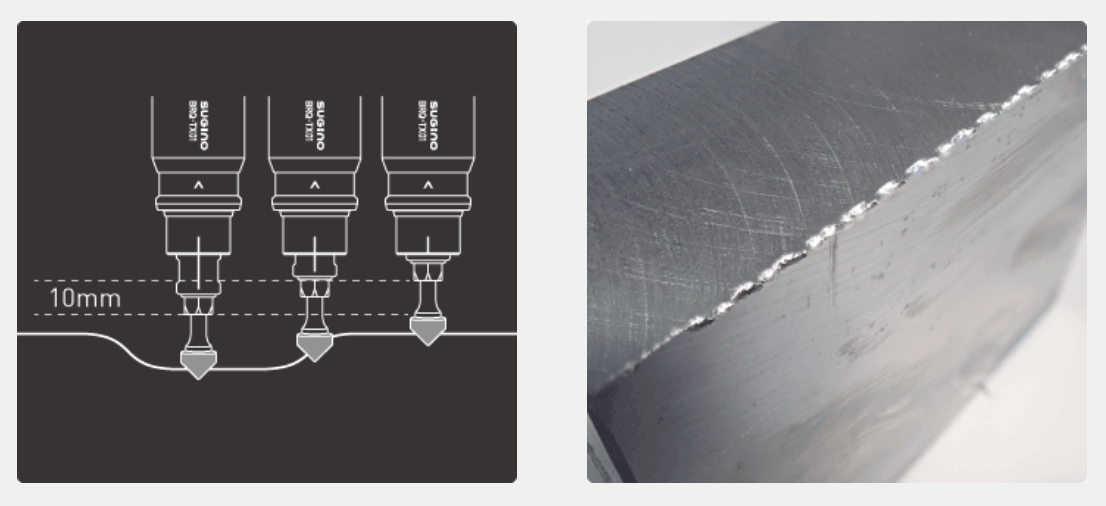

AXIALLY FLOATING TYPE

The axially floating type utilizes a mechanism that extends and retracts in the Z direction. It is ideal for deburring the edges of workpieces and is often used to deburr the contours of castings, and burrs that remain after machining.

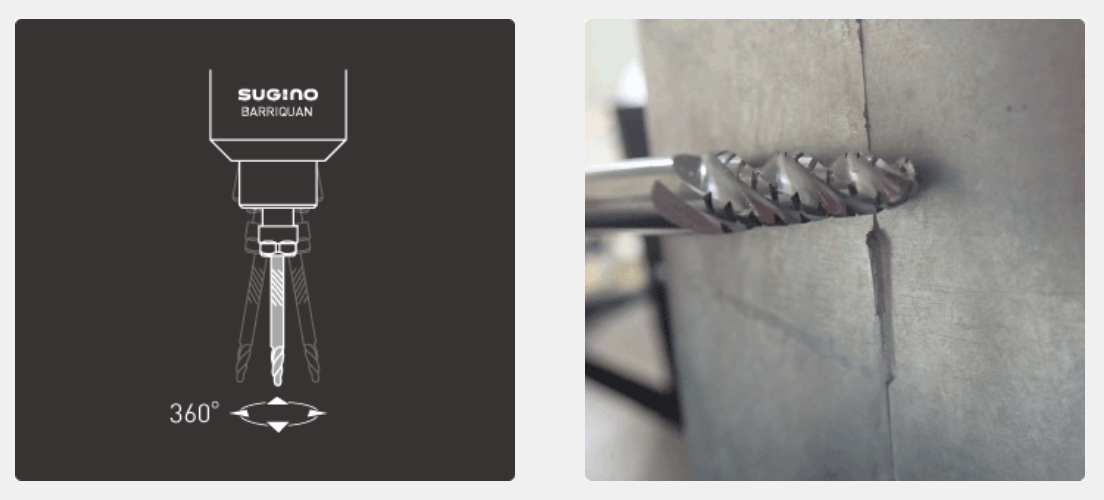

TILTING FLOATING TYPE

With this type, the tool is tilted to the workpiece. Suitable for protrusions and burrs that occur on the "surface" rather than the edge of a workpiece. It is often used for parting line removal of aluminum die castings, etc., and is mainly suitable for deburring using robots.

See If Automated Deburring Fits Your Parts →

Explore model types, options, and see what may work for your process.

More ways to learn about deburring automation:

Why Float Deburring Works When Manual Doesn't

Consistent Results Without Operator Dependency

The floating mechanism allows the tool to move axially and/or radially, maintaining uniform contact pressure. This prevents over-cutting, missed burrs, and excessive material removal. Each part receives the same finish regardless of batch size.

Designed for Automation, Not Hand Finishing

Lock in predictable performance, shorter setup times, and repeatable results across production runs. In a machining center, or in a stand-alone cell that utilizes a light payload robot.

Scales with Your Production

Once programmed, the system runs continuously, freeing skilled labor for higher-value machining tasks while increasing throughput and consistency.

- Skill-dependent results

- Variable quality

- Difficult to scale

- Labor-intensive and costly

AUTOMATED DEBURRING

- Repeatable, controlled process

- Consistent edge quality

- Scales with production demand

- Reduces labor dependency

More Than a Tool: A Process Solution

Sugino doesn’t just supply deburring equipment. We help machine shops:

-

Evaluate parts for automation feasibility

-

Test deburring processes before investment

-

Design repeatable, production-ready solutions

-

Reduce risk when transitioning away from manual work

Our goal is simple: help you remove deburring as a bottleneck—not add complexity.