As we have discussed previously, there are many ways to deburr. This week we’re taking a closer look at High-Pressure Water Jet Deburring. The first thing that bears mentioning is that CNC-controlled, high-pressure water jet deburring produces accurate, repeatable, and predictable results. For the right situation and parts, it’s an ideal solution to remove burrs.

High-Pressure Water Jet Deburring is exactly what it sounds like. Pressurized water is precisely focused through CNC control to remove burrs and chips in and around parts. Depending on the cleanliness specifications, this can be performed submerged or in an open-air environment. Open-air washing/deburring targets specific areas of the part where the water jet is focused. Submerged will clean the entire part, internally and externally.

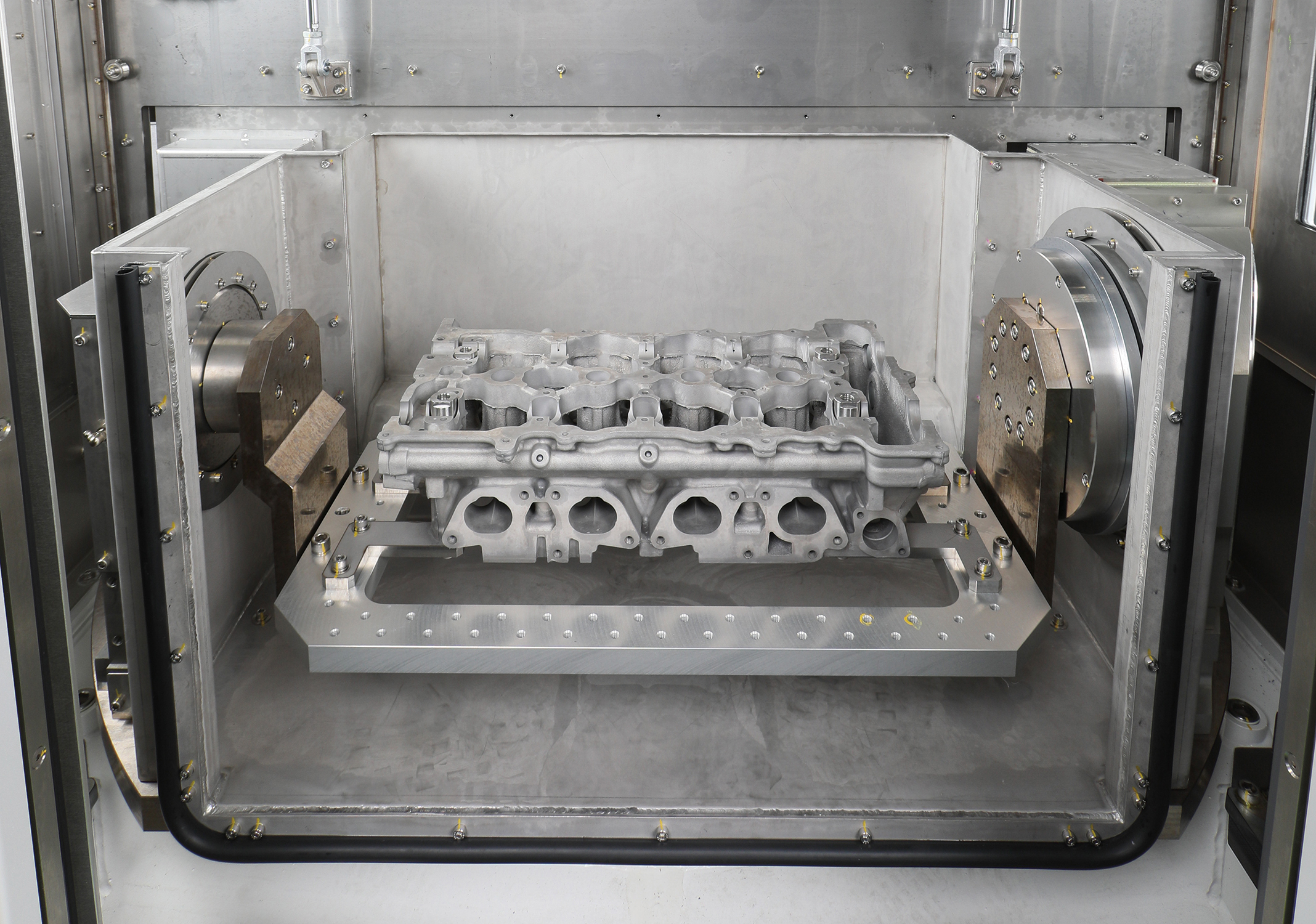

A look inside the Sugino JCC 421.

Complex Parts, Cleaner Parts

High-pressure water is optimal in situations where hard-to-reach areas need to be deburred. CNC control enables high positioning accuracy and penetration as the nozzles are directed to cross holes, deep holes, and tap holes to effectively remove chips and burrs. Even workpieces with complex geometry are often a great match for this method, making it an ideal process for industries with tight specifications. Water jet deburring is also recommended when parts cannot be exposed to corrosive chemicals or heat. It is deposit-free, residue-free, and leaves your parts cleaner, shortening the cleaning process.

There are a number of features that can be incorporated into the deburring process to save time and steps, including tooling, filtration, automation, and specific nozzles to optimize washing and deburring. Vacuum dryers and cleanliness evaluation systems can also be added to improve efficiency and reduce cycle time. The end result is a system that meets your specs – effectively, efficiently, and with fewer processes.

Before and After

Is it the Right Fit?

So how do you know if high-pressure water jet deburring is the right method for your production challenge? In general, Class One through Class Three burrs can be removed by high-pressure water or by brush, assuming the burr passes the Lead Pencil Test*. But some Class Four burrs are also removable as well. (Note: we reviewed burr classes here).The best way to determine if it’s a match: Test your parts to see if high-pressure water jet deburring is fit for your manufacturing process.

The turntable inside the JCC 421 adds the ability to have two operations happening within the same system.

Water jet deburring is an effective, CNC-controlled method for deburring metal parts requiring a high level of precision and repeatability. This method can both deburr and clean parts in one eco-friendly process, getting rid of loose burrs and chips even in deep holes – all while leaving the part clean and free of debris.

*Lead Pencil Test. – If a burr can be removed by prodding it with a 0.7mm mechanical lead pencil tip (without breaking the lead), the burr is removable by high-pressure water or brush.