The demand for affordable, efficient batteries is ever-increasing. As a result of the automotive industry’s increased production of hybrid and electric vehicles and the effort to manage climate change with alternative, clean fuel sources, the global battery market is growing faster than expected. The need to process raw battery materials is growing along with it.

But processing battery materials cleanly and effectively is a challenge.

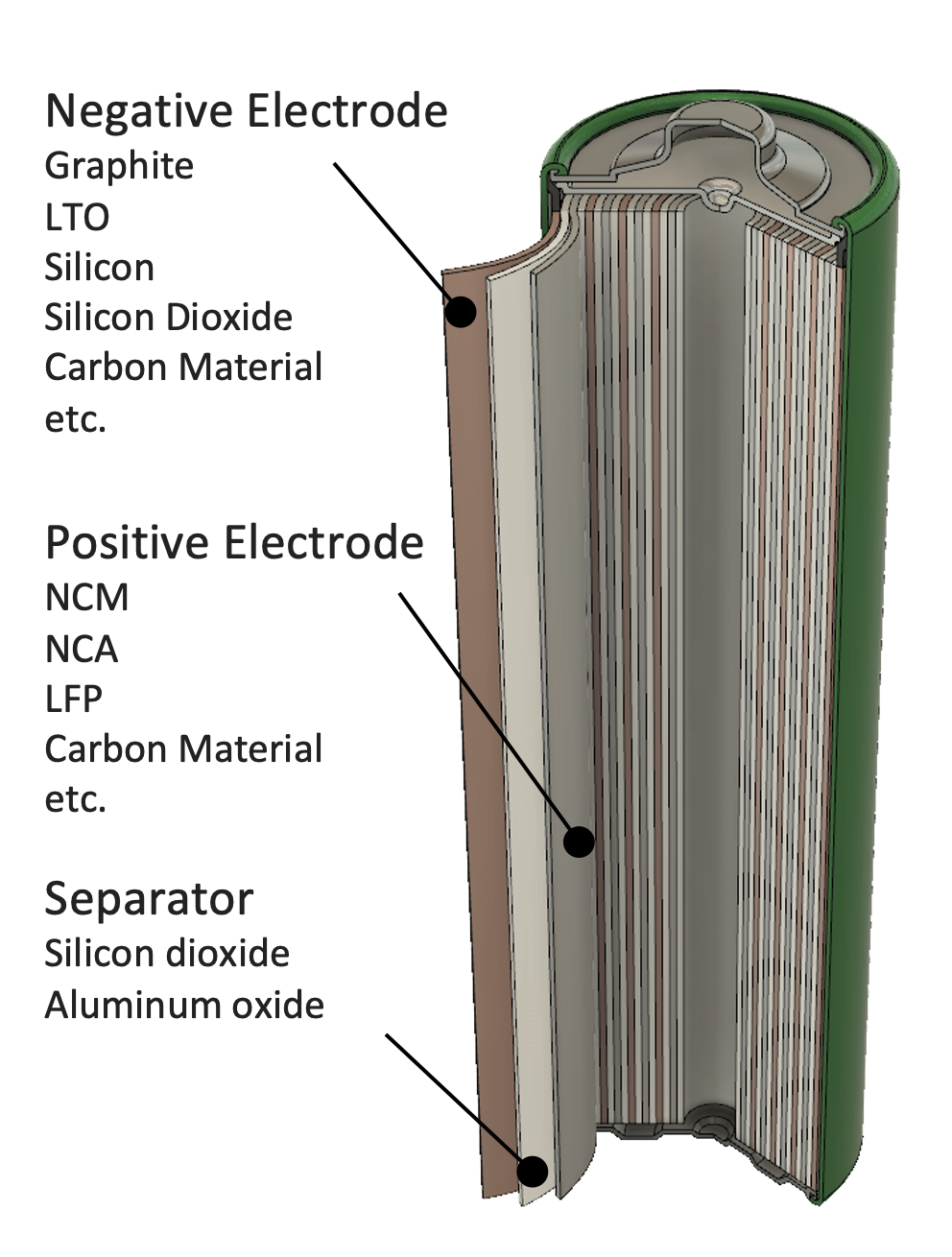

Capacity and conductivity must be maximized, but safety, sustainability, and battery life are all concerns that need to be addressed.

So how do you optimize energy density while minimizing volatility?

Change your battery materials: solid-state battery materials deliver high energy density without the dangers associated with traditional lithium-ion batteries.

Or you can change the way you process your raw battery materials.

Wet-jet milling can produce nano-sized, high-surface particles, optimal for battery development.

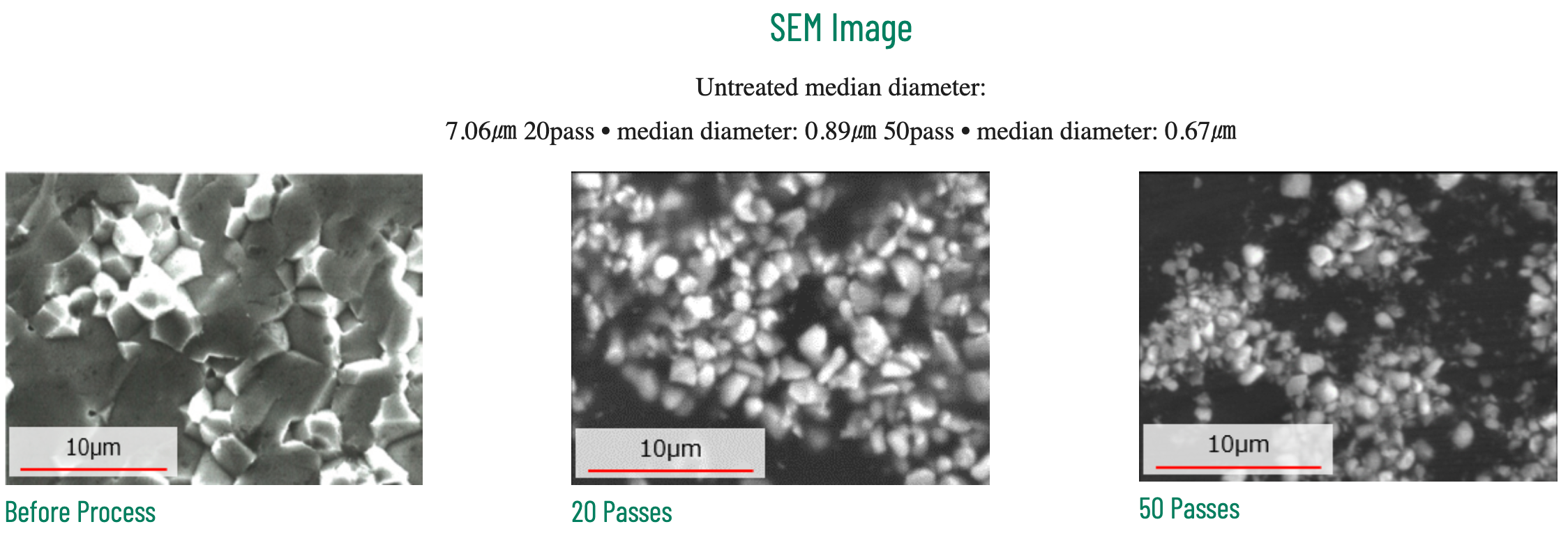

Star Burst reduced particle size significantly and evenly for both Oxide solid electrolyte and Sulfide solid electrolyte.

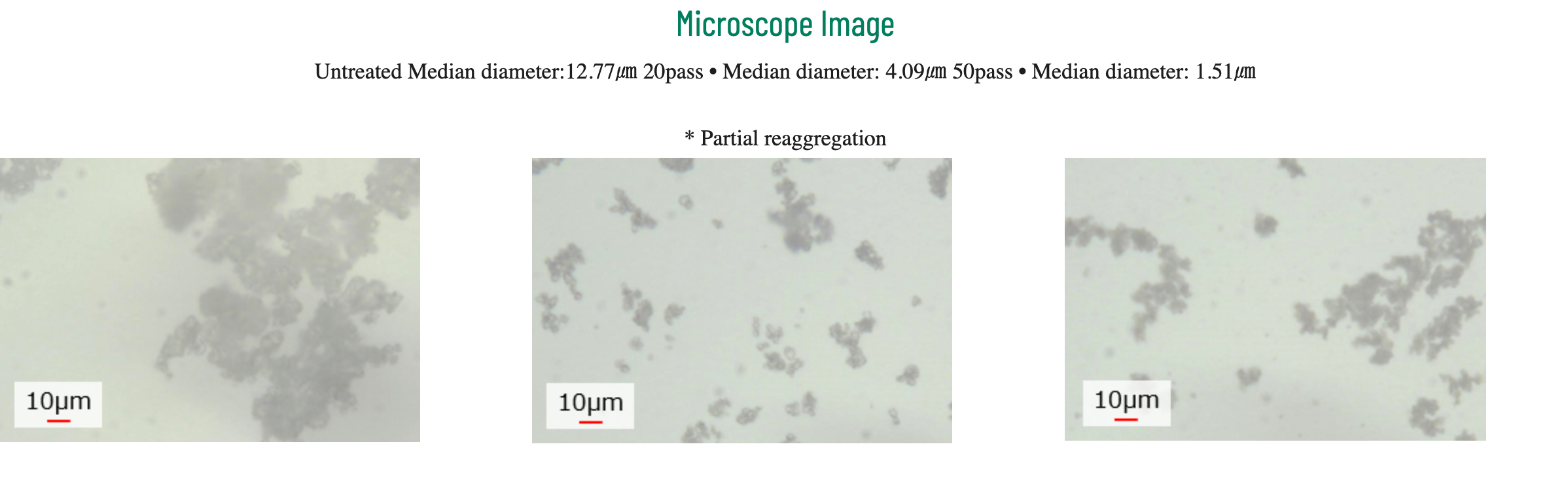

Carbon Nanotube, CNT, can be used as a conductive additive in batteries. But CNT is firmly agglomerated. Star Burst can homogenously disperse CNT without compromising the tube structure, maximizing surface area, and improving conductive properties.

So, no matter the material and wherever your research takes you, let Star Burst be your partner. Material processing and homogenization with minimal contamination.

Good. Clean. Technology.