Skiving or Roller Burnishing vs. Grinding & Honing

For hydraulic applications in demanding industries like construction, agriculture, and mining, pipe interior finishing has long relied on grinding and honing. However, skiving and roller burnishing offer significant advantages in cost, precision, and performance.

Unlike traditional methods, skiving and roller burnishing provide faster, cleaner, and more efficient results. This process can replace grinding and honing while delivering a range of benefits, including:

- Faster Processing: Skiving is up to 70% faster than honing, streamlining production.

- Superior Surface Finish: It produces a smoother, more uniform surface than grinding and honing.

- Lower Tooling Costs: A single tool is used for skiving, whereas honing typically requires multiple.

- Environmental Benefits: Grinding and honing produce sludge that needs to be disposed of safely, skiving does not generate sludge.

- Enhanced Material Strength: Roller burnishing strengthens the material and reduces friction through compression.

A skiving and roller burnishing tool can run in one or two directions. When performing both processes in one pass, the combined skiving and roller burnishing head delivers significantly reduced machining times compared to honing. In two-way processing, it will skive on the forward pass and burnish on the return for finely tuned, optimized results. Sugino’s retractable skiving blade prevents scratches on the finished surface.

Vertical vs. Horizontal Skiving

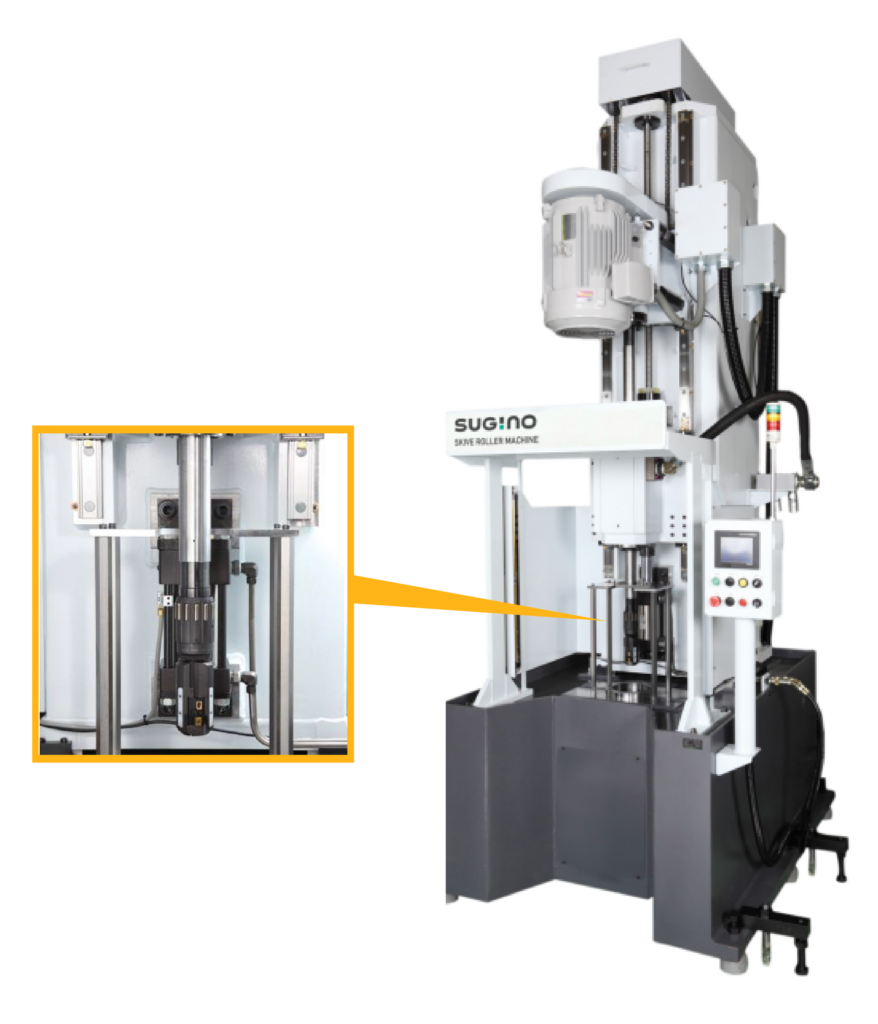

Sugino’s skiving and roller burnishing solution is available as a tool to fit your current skiving machine or as a full-machine system.

Sugino is the sole manufacturer of the vertical skiving machine. The vertical direction delivers inherent benefits due to the tool positioning. This machine can process bores up to 4 ft 3 in. (1300 mm) in length and 6 in. (152.4 mm) in diameter, making it ideal for processing hydraulic cylinders for forklifts, shock absorbers, and oil and air cylinders.

The vertical configuration requires less floor space than a typical horizontal machine, about 50% less. The Skive Roller machine’s unique vertical design takes advantage of tool weight and gravity, delivering superior accuracy and surface finishing compared to a horizontal system. Plus, the vertical design means that chips evacuate downward in front of the tool and don’t need to be flushed out or pushed along, unlike horizontal machines.

Chip disposal is expensive and can be dangerous to your workforce. Sugino’s Skive Roller machine has an optional chip shredder that minimizes chip size, reducing the hazards associated with disposal.

Sugino vs. the Competition

Sugino’s vertical skiving machine differs from the competition. Its vertical design has half the footprint of its horizontal counterpart (and it’s much less expensive too). The design is inherently more stable and precise than a horizontal setup and has smoother chip removal. And the lifespan of our rollers and mandrels is 3x longer.

Our sales engineers and top-rated service team are always available to provide the machinery, know-how, and expertise to design the perfect system, swap out parts, or troubleshoot.

Key Takeaways

- Skiving and roller burnishing outperform grinding and honing in hydraulic applications, offering benefits like faster processing and superior surface finishes.

- Skiving is up to 70% faster than honing, using a single tool, which lowers tooling costs and eliminates sludge waste.

- Sugino’s vertical skiving machine requires 50% less floor space and delivers greater accuracy with efficient chip disposal compared to horizontal machines.

- Sugino’s design features longer-lasting rollers and mandrels, along with excellent technical support from sales engineers.

- The vertical skiving configuration enhances material strength while optimizing machining times in both skiving and burnishing processes.