WATER JET DEBURRING MACHINE

JDM

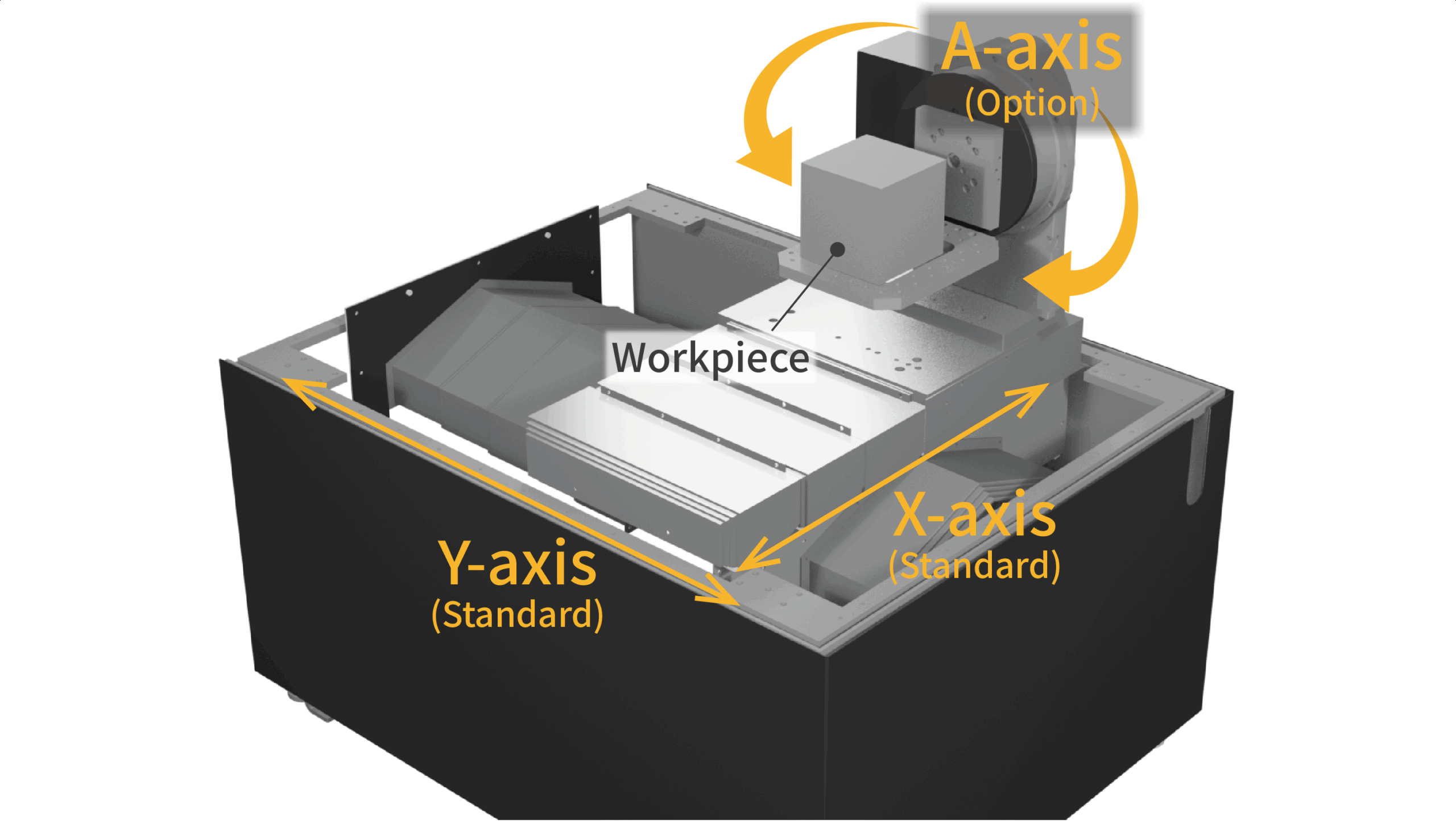

Equipped with an A-axis, it easily reaches the workpiece’s mounting surfaces.

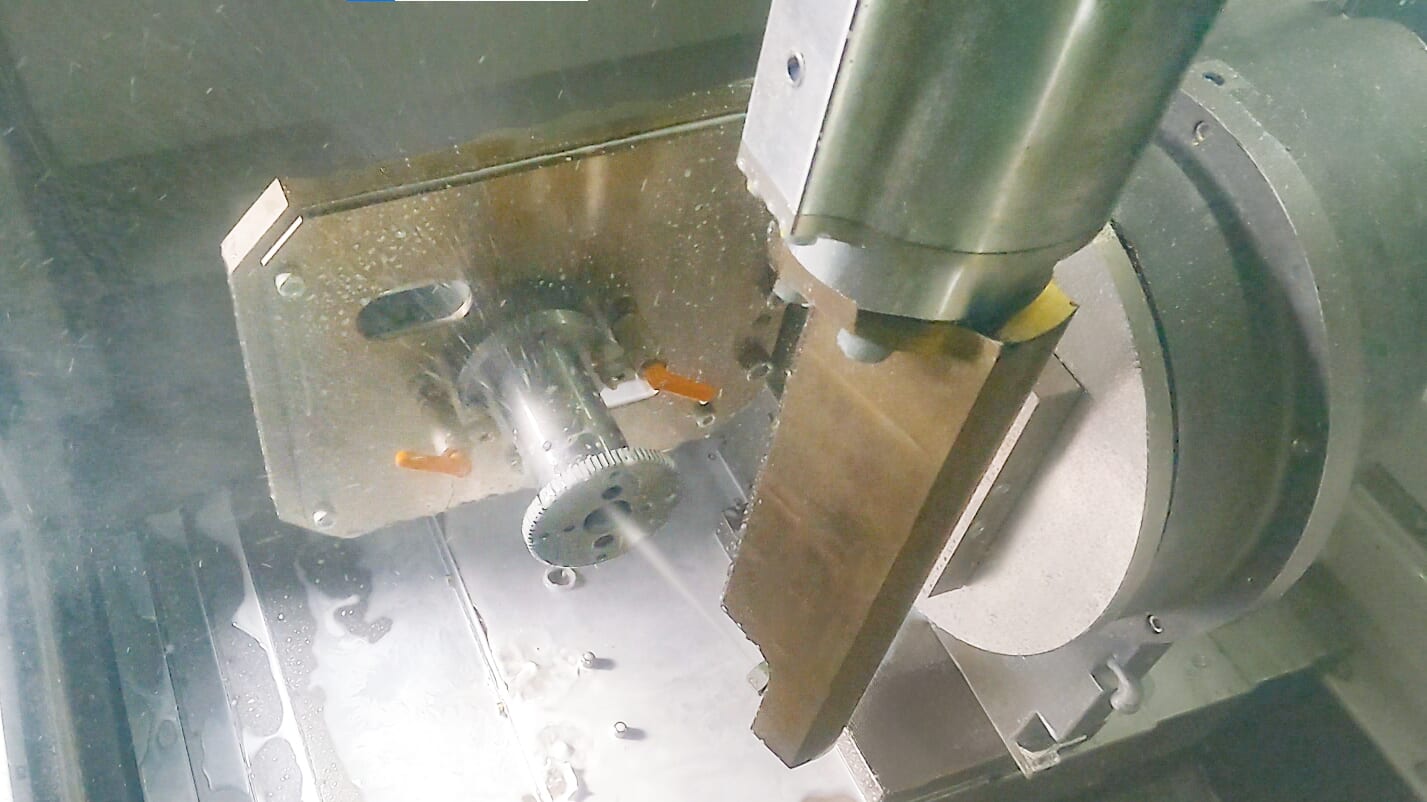

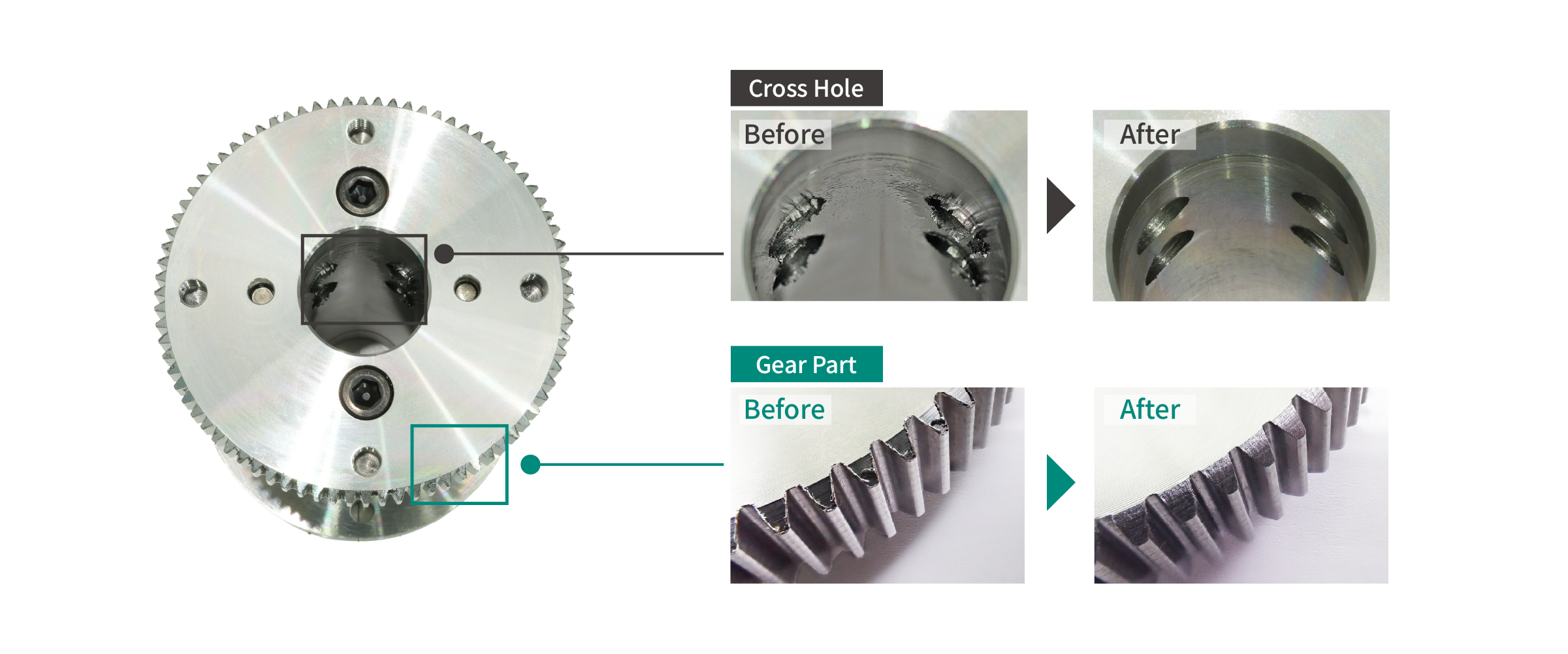

Targeted deburring with high-pressure water at up to 70MPa / 10,000 PSI

While the conventional JCC 104 HYBRID deburred at up to 50 MPa, the JDM (Jet Deburring Machine) increases pressure by 40% to a maximum of 70 MPa. The increased pressure improves burr removal efficiency, supporting automation and labor reduction of manual deburring.

What is water jet deburring?

Water jet deburring removes burrs using the impact force generated when high-pressure water is ejected from a nozzle. It is precise, CNC-controlled, and achieves repeatable results.

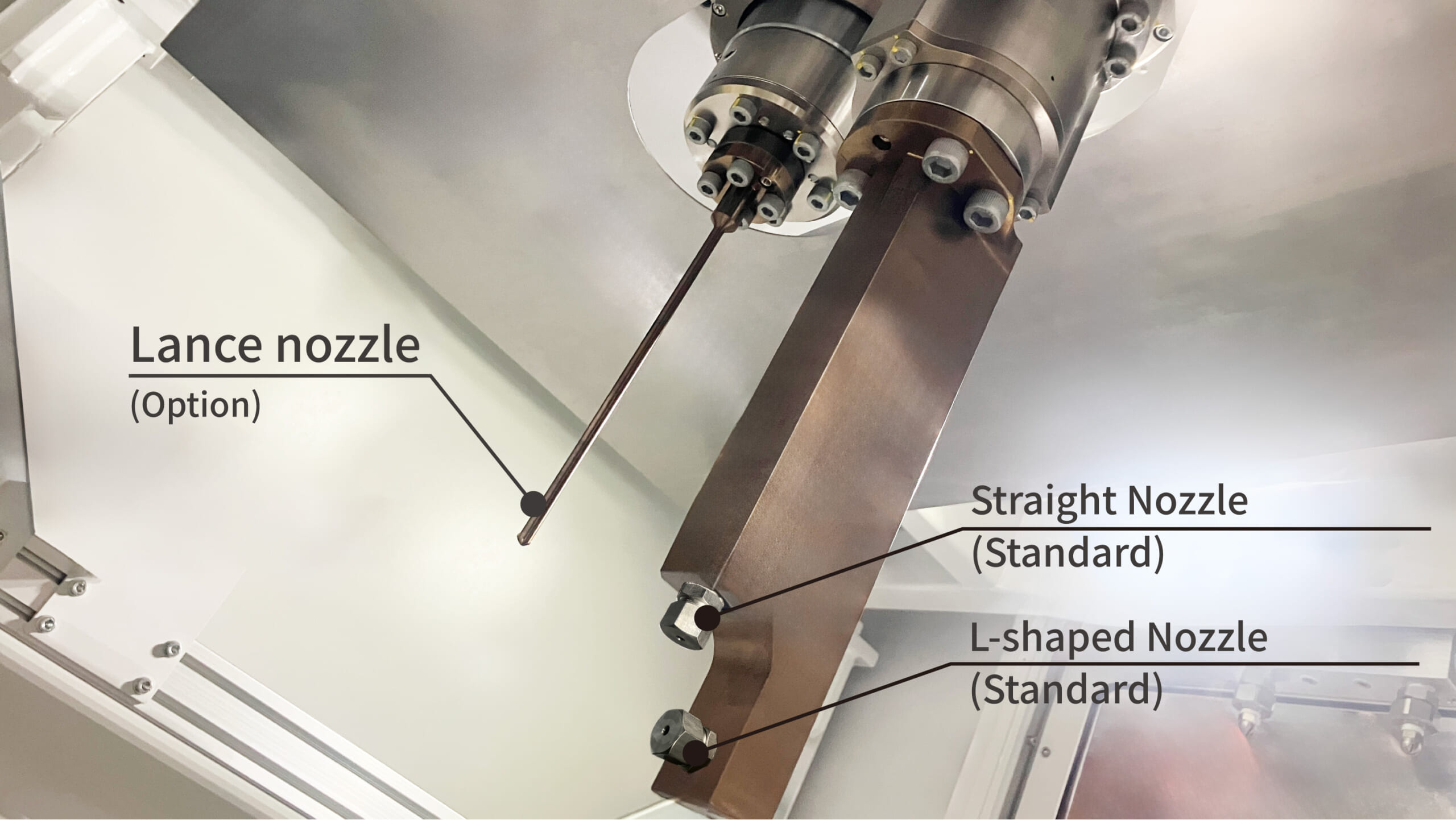

New Dual-Flow Nozzle reachs five sides of the workpiece

Equipped with an A-axis, allowing access to the back side of the workpiece

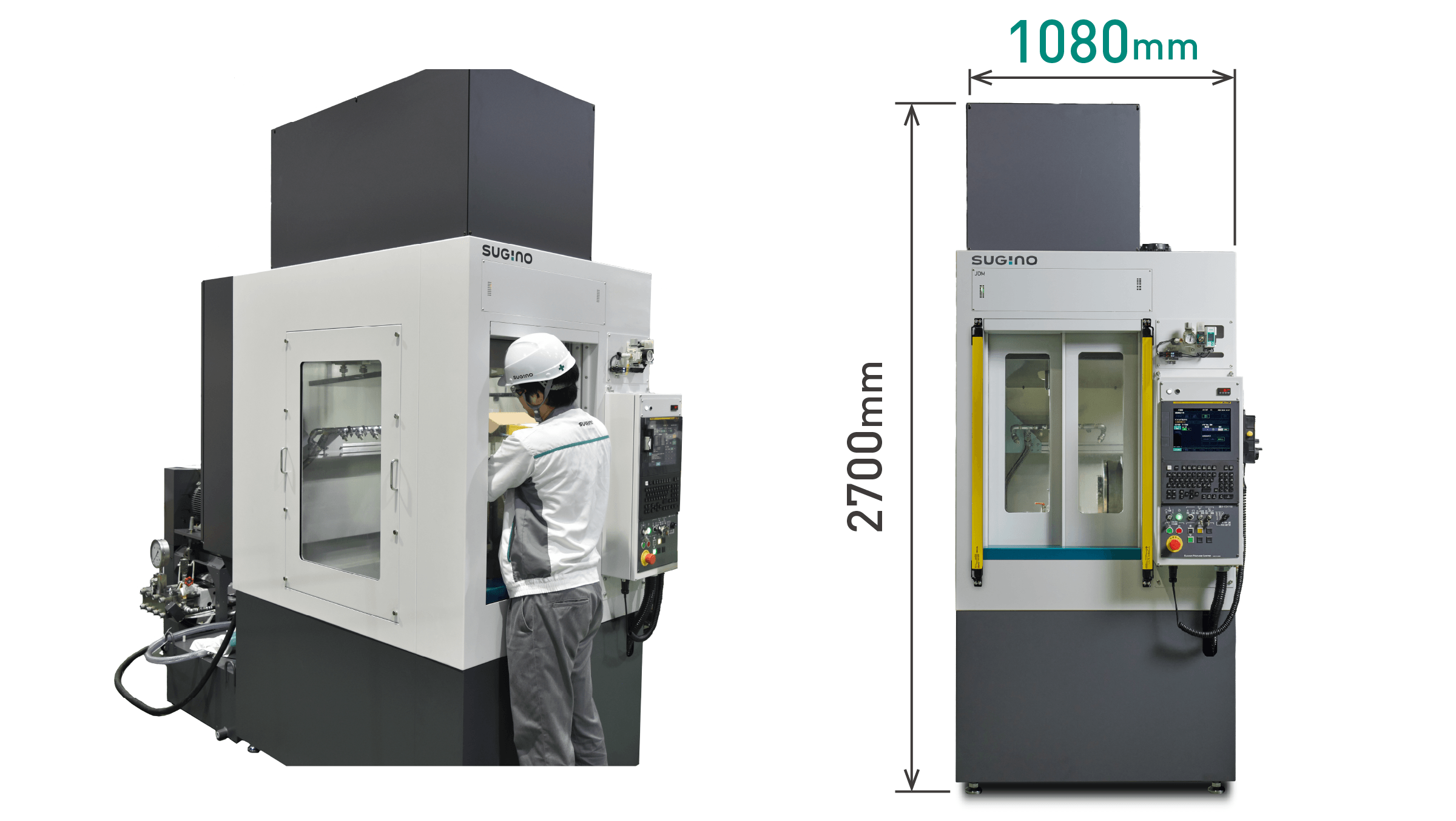

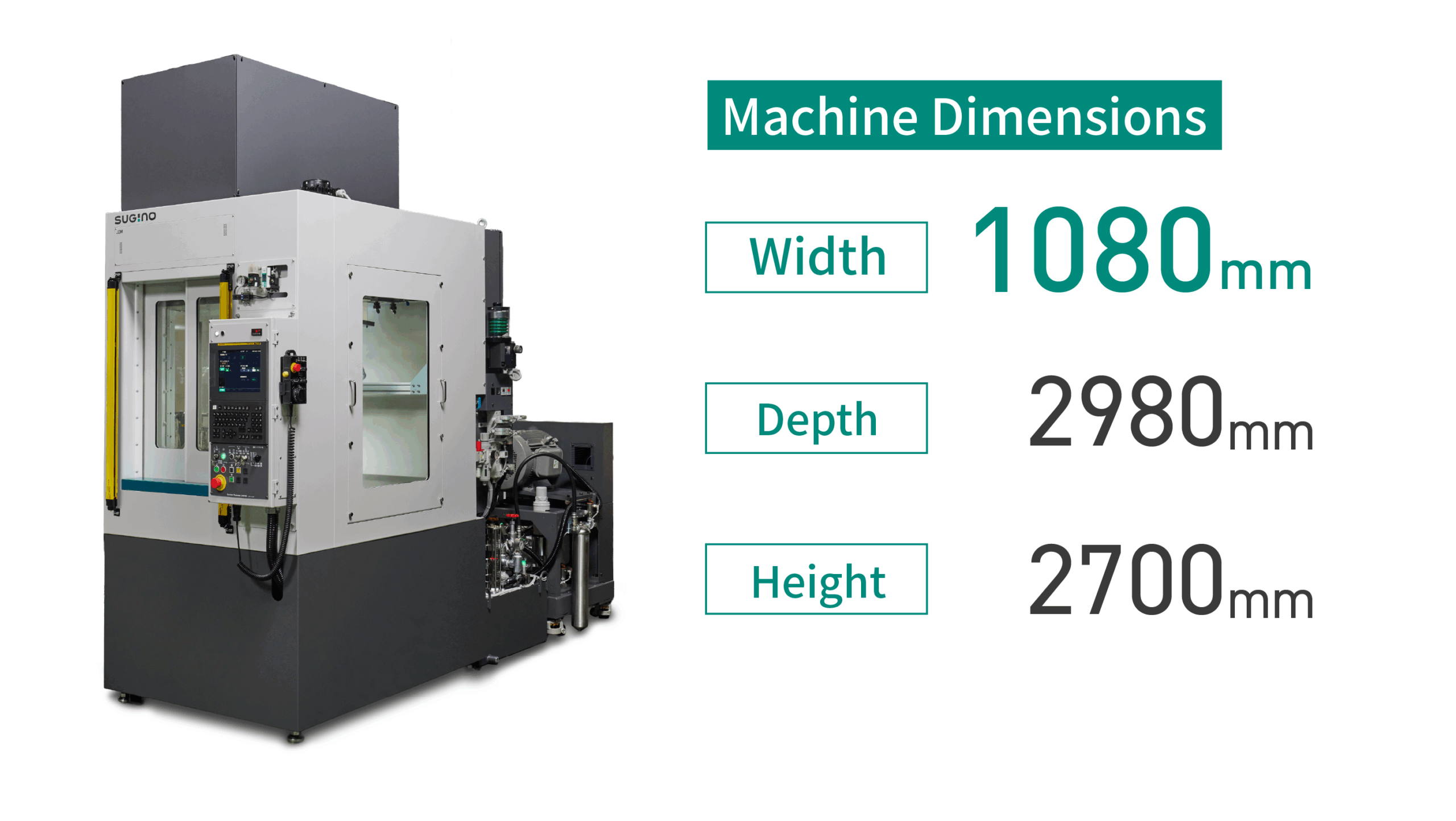

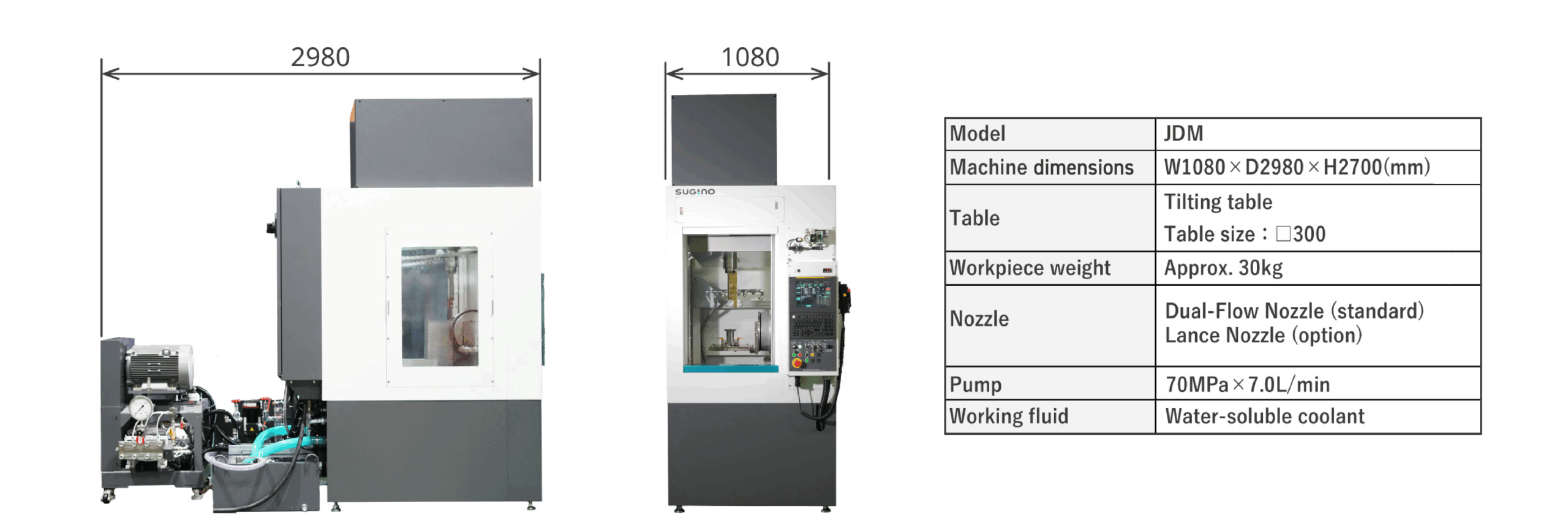

A compact deburring solution, only 1,080 mm wide

Our robust parts testing process shows you exactly how JCC can benefit your production process.

We offer parts testing at our Wixom Technology Center. And our results report is second to none. To discuss your project or testing, get in touch - or request a call or email at your convenience.

Classification of Burrs

Problems Burrs Create

The Parts Testing Process

A guide to getting the most out of the parts testing process for deburring. From sending parts to working with your sales engineer.