Turntable with Integrated Submerged Cleaning and Deburring

421-UTE U-Jet - CNC Turret /Turntable

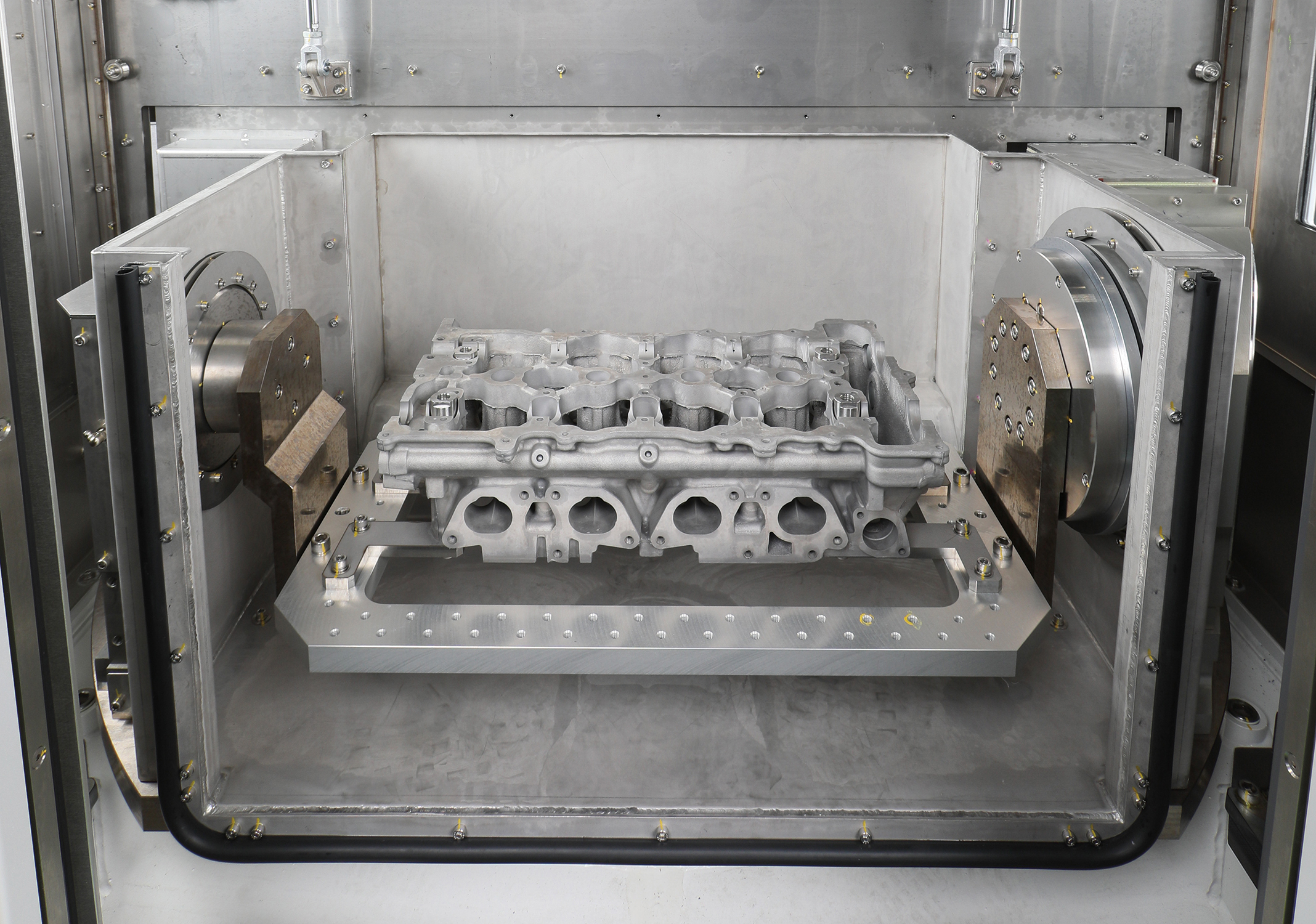

The JCC 421 UT combines the efficiency of our part handling turntable unit with the effectiveness of submerged washing and deburring in one machine - to give improved cleanliness and a more rapid feed rate for greater productivity. The load and unload time can now be more productive, since the loading zone and the wash/deburr zone are separated with the turntable.

Features

- Non-washing time is reduced compared to conventional models

- Manual load or use automation. Top-load gantry, side-load from conveyor, or front-load with a robot.

- Saves floor space

- Extended cleaning function with servo motor driven pump

- Applicable work size: 650 x 450 x 450 mm

Loading/Unloading via Turn Table

Submerged Washing Station

Option: Blow-Off Station

Jet Pump with Servo Motor

Cleaning and deburring of stator housing and inverter case

Cleaning and deburring of cylinder head and cylinder block

Removal of chips in water jacket

Simultaneous cleaning and deburring of many small parts such as valve body and ABS control unit mission case

Cleaning and deburring of large aluminum cases

Think You've Got Specs We Can't Achieve?

We're engineering solutions

that keep up with ever-changing

specifications for your industry.